Other products

Transport device for waste containers

Save time, money and energy - protect your health!

A 1100 liter waste container can weigh up to 1000 kg when its full. This is a great burden for the person who has to take the bin to the collection point. It becomes impossible if this container has to be transported over a ramp. Residential complexes often have many containers that have to be brought to the collection point on the collection day. We have a solution to this problem.

Our transport device for standard 1100 liter waste containers makes it possible to transport standard waste containers without having to carry out any structural work on the waste containers themselves. Several of our transport devices for waste containers can be coupled together. Our battery-powered tugs can be used as towing vehicles, but also other vehicles e.g. tractors and forklift trucks or similar.

Procedure: The transport devices are placed next to the waste container. One side of the transport device is opened – the waste container is pushed in – the side is closed again – and that’s it. One person can bring several waste containers to the collection point without great effort and in a short time.

Impressions

Screening bucket for mini excavators

Screening – separating – mixing – aerating with the screening bucket for mini excavators!

The robust screening bucket was designed for attachment to the mini excavator. The excavated material can also be processed cost-effectively with the screening bucket on smaller or narrow construction sites, particularly in landscaping and paving work. The screening bucket has also proven its worth when cleaning and aerating topsoil and play sand.

The screening bucket is designed for excavators with an operating weight of 1.5 t and above and the changeover time is short thanks to the MS01 mechanical quick coupler from Lehnhoff. The screening bucket is equipped with screen plate segments that are arranged at a defined angle and has a capacity of approx. 100 liters.

The screening bucket with variable screen geometry saves energy, is user-friendly and can be used very flexibly thanks to the interchangeable screen plates. There are currently seven prefabricated screen panel types (A to G). Screen plates with customer-specific screen geometries can also be realized.

The hydraulic motor can be operated without a leakage oil connection. The pressure is protected by a shock valve. The Danfoss OMS orbital motor is particularly suitable for continuous operation under difficult conditions.

Impressions

Levelling system

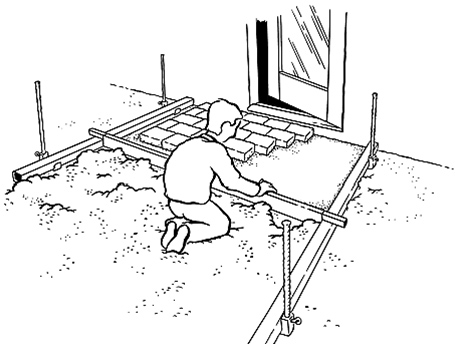

Another innovative product from Weber Baumaschinen & Fahrzeuge GmbH is the new levelling system for creating the paving subgrade. From the common practice of creating the planum with spies buried in fine chippings or similar you have to say a complete mental goodbye. The Weber levelling system consists exclusively of high-quality, stable materials such as aluminium profiles or anodized metal parts. The special feature of this system is the height-adjustable fittings, which open up completely different possibilities. With the help of this technique, a planum can be pre-constructed three-dimensionally, virtually in the air.

The spikes with the height-adjustable fittings are hammered in at the corner points. Next, place the sturdy aluminum square tubes in the fittings. With the help of the height-adjustable fittings, the associated aluminum pull-off rulers and a spirit level, you can easily set or change a horizontal or a slope.

If everything is set correctly, you can easily estimate the amount of ballast required. Now remove the aluminum square tubes (the hammered-in spikes with the adjusted fittings remain), place the ballast and compact it. Now place the aluminum square tubes back into the fittings and apply the gravel.

The square-edged aluminum pipes are not buried in the subgrade, but lie with their lower edge on the subgrade. This circumstance has some advantages, e.g. wider areas can be easily levelled by placing one of the aluminum square tubes on the edge of a levelled area (thus having the correct height) and simply continue constructing next to it with spikes, fittings and aluminum tubes. Besides, after removing the aluminum square tubes, you don’t need to fill the resulting channel.

Even after the gravel has been placed, you can still easily change the horizontal or gradient (without having to dig deeper into the pipes or underlay them). You now use the aluminum screeding rulers included in the set to level off the subgrade. Done.

In combination with the Vario system from Weber, there are even more interesting possibilities. Time savings of up to 40% when creating the planum are the rule after a short training period. The entire technology is of course independent of the paving stone or slab thickness. One set contains 12 meters of aluminium square tubing, 8 ground pegs with height-adjustable fittings and 3 high-quality aluminium pull-off rulers (2m, 3m and 1.2m).

Impressions

Battery cable layer KV 01

Laying cables like a pro

With the KV-1 wire laying machine, the working area of the robotic lawnmower is defined quickly and precisely. Thanks to its powerful battery-operated electric motor, work can also be carried out in the evening and on Sundays and public holidays without any noise pollution. The laying speed is infinitely variable. The high final speed makes it possible to cover the area of a soccer pitch in approx. 20 minutes.

The cable is laid without tension. The laying depth can be infinitely adjusted from 0 – 5 cm. Thanks to the soft start when driving forwards and backwards and the extreme maneuverability, even tricky areas can be worked on precisely. In addition to cable drums from all robot mower manufacturers, drums for rubber cables up to 4.4 mm in diameter can also be fitted for large-area mowers.

Data sheet

The robust design of the cable layer guarantees a long service life. The operator has also been taken into consideration. The handle height of the cable layer is adjustable and can be adapted to the desired working position. Cutting tools can be changed quickly and easily. With the handle folded down, the KV-1 can be transported in a space-saving manner. Naturally, the battery and electronic charger with overcharge protection are included in the scope of delivery.

The KV-1 not only impressed the expert jury at the Demopark innovation show in Eisenach. Awarded a silver medal, it met with great interest from visitors. During the trade fair, the KV 01 was able to show what it is made of. Together with a local motorist, a robot mower was installed on a nearby customer’s property in a very short space of time.

The KV-1 battery cable layer was developed by practitioners – with practitioners – for practitioners. It is constantly being optimized. The wishes and opinions of colleagues are taken into account. In order to be able to lay cables in heavy soils (dry clayey soil, stony subsoil, old, firmly grown soils) without any problems, the KV-1 was equipped with an additional weight of 20 kg in addition to its own high weight. Requests for infinitely adjustable handles and adjustable distance gauges were also realized, as was the desire to be able to mount even larger cable drums. 500 m of rubber cable up to a diameter of 4.8 mm – no problem today!

Cables were laid live at the demopark trade fair stand in 2017. Motorists were able to become active themselves. Everyone was impressed by the handling of the appliance. Discussions between the motorists were particularly interesting. Skeptics, who initially criticized the heavy weight, discovered during their live trials that laying on the heavy floor at the exhibition stand is easier and more comfortable with additional weight. Even the smallest radii could be realized without any problems. Motorists who have been using the KV-1 cable layer for their installations for years convinced the skeptics. At the same time, they pointed out another unbeatable advantage of the KV-1 cordless cable-laying machine: unlike petrol-powered machines, the KV-1 eliminates the enormous vibration load during work. The wrists are spared. For many, this is another important argument when choosing a suitable cable laying system.

Impressions

Spare parts and operating instructions

You need…

…spare parts, spare parts lists, operating instructions, brochures, help to adjust the brake correctly, help to adjust the V-belt correctly, a demonstration, a loaner, a special set-up or whatever? Get in touch with us! We will provide you with the requested information immediately.

Our hotline

0049 2753 / 60 39 80